As we near the end of July, and the summer sun builds the sweat on my brow from simply standing outside, I am relieved when I remember that it’s almost harvest ale season! Speaking of harvest season… hops harvest 2018 is almost here! Here are some pointed on determining when your plants are ready. There are multiple ways to check readiness for harvest, and I recommend utilizing as many avenues as you are able. The most reliable way to know your hops are ready is by submitting samples to a lab.

-When to send in hops for analysis?

Should: If you are new to growing hops, send in a sample when you notice the color of the cone and the color of the lupulin start to change. Lupulin will change from a bright yellow to a deep golden color as cones ripen.

Must: After hops have been dried and conditioned to <12% moisture, send a sample in for analysis called the brewer’s test (alpha and beta acids, Hop storage index (HSI), essential oils). The results of these analyses go to the brewer and provide confirmation of quality. It helps the brewer know the quantity of hops needed in beer recipes.

-How to sample your yard:

Ideally, collect 4 cones per plant, 1 from each quadrant, and at least 60 cones per cultivar from as high as possible.

–What do the different tests mean (brewer’s test)?

Alpha acids – Bittering

Primary alpha acids: humulone, cohumulone, adhumulone

Beta acids – Longevity, antimicrobial properties

Primary beta acids: lupulone, colupulone, adlupulone

Hop Storage Index (HSI) – % alpha acid loss after 6 months at 76 degrees F. With proper refrigeration, hops maintain most of their quality two years after harvest.

Essential oils – flavor & aromas

As a grower, you also should check your hops often for physical changes to the cone. If you have access to a hand lens (10x) or a dissecting scope, identifying ripened trichomes can provide a valuable understanding of when cones are ready.

When to harvest (look, feel, smell):

- Cone weight – cones become lighter in weight

- Cone moisture – feel less moisture in the cone overtime; dry matter content down to 20-25%

- Lupulin color – Lupulins turn from white/white yellow to golden

- Lupulin shape – Lupulin glands near full, like an acorn, and become opaque

- Lupulin/cone smell – No grassy of alfalfa type smell in crushed cones

- Bracts – become papery and lighter in color; edges start to brown

Conducting dry matter tests, are another option you can include, though this method may not line up with acids and oil maturity.

Limited target dry matter percentages are available for a few varieties (Hop Harvest Guidelines, ISU Hop Workshop Series 2017):

- Cascade – 22%

- Centennial – 23.7%

- Chinook – 23.4%

- Fuggle – 21%

- Galena – 22%

- Mt. Hood – 23%

- Nugget – 23%

- Tettnang – 21%

- Willamette – 20%

To determine the percentage of dry matter, start with 5-10 random samples of the same variety from side arms throughout your hop yard. If possible, take samples within 1-2 feet of the top of the trellis, and when morning dew or rain is not present. Combine the 100 to 150 cones in a bucket. With your collection complete, you can now determine the dry matter. You will need a scale that calculates weight in grams.

Using the scale, weigh an empty container and the container with the freshly picked hops, keeping record of both weights. Next, you will dry your hops sample down to zero percent moisture. You can do this using a food dehydrator, a Koster Moisture Tester, or a microwave or conventional oven.

- Food dehydrator – drying cones between 140-150 degrees F overnight allow cones to dry to 100% moisture.

- Koster Moisture Tester – continual monitoring of cones is necessary with this method as cones are dried quickly.

- Microwave or conventional oven – this method also requires regular monitoring to prevent scorching your cones. If using a microwave, dry at 50% power and check cones every 30 to 45 seconds (this will prevent heat build up in the microwave).

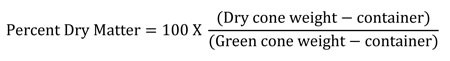

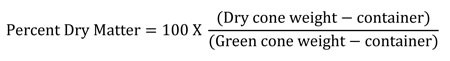

When the cones reach a stable weight, weigh the dry hops and record the weight. The following equation may then be used to calculate the percent dry matter of the cones.

FAQ:

What if my alpha and beta acids do not meet the industry standard range?

If your hops’ acid contents do not test in the standard ranges, there could be a couple of issues. Your hops could still be maturing and therefore, you should wait 4-7 days to test again. Your hops may also not be fully mature. This often occurs in the first 1-3 years of harvest. As yield increases in the first few years, you should expect your acid levels to improve as well.

How long is the harvest window for hops?

The harvest window for each hop cultivar varies. The window is generally 7-10 days upon ripening.

I separated my cones from the bine. Now what?

The moment hops are separated from the bine, the clock begins ticking before the compounds begin to break down and oxidize. Summer heat and humidity increase oxidation and chances of mold and mildew developing on freshly harvested hops, which may contain up to 80% moisture. You have roughly 45 minutes to begin drying your hops or to bring them to a processor before they begin to break down.

Why do I need to dry my hops?

Hops may be incorporated into the brewing process in several forms. Wet or fresh-hopped beers (harvest ales) utilize hops directly from the bine, and generally bring out the most aromas from the hops. Because of the proximity of growers to brewers, most hops are dried to preserve the aromas and acid content present in the cones. From drying, they can be added to brewing recipes, or may be further processed into products such as pellets or hop extract.

Are there food safety guidelines I should be aware of?

According to the FDA, hops used in commercial production of beer are eligible for exemption from the FSMA Produce Safety Rule regardless of what point in the process they are added (before or after the boil). In the bill of lading, invoice and/or the unit of sale for wet hops needs to have the words,

“not processed to adequately reduce the presence of microorganisms of public health significance”

on it. In addition, the purchaser of the hops needs to provide proof that they actually used the hops in the making of beer. That can be a letter, but it needs to be written and kept by the seller.

**One last and very important note: during this critical time of harvest preparation, do not forget to regularly scout your hops. Spidermites, aphids, hop downy mildew and other pests can completely wipe out your harvests at a rapid rate.**

Upcoming Events

Hops Field Day

- August Field Day – 6th Meridian Hops

4200 Alphonse Rd, Yankton, SD 57078

Saturday, August 4, 11 AM – 4 PM

UNL Hops is teaming up with the South Dakota Specialty Producers Association & 6th Meridian Hops to present a Growing Hops Tour. The event will include a tour of 6th Meridian Hops, oasting, baling, and pelleting demonstrations, a presentation on “Late Season Downy Mildew Management,” and opportunities for networking. Hop producers, interested growers, brewers, and the general public are welcome. The event is free. Please RSVP at Growing Nuts & Hops SDSPA Tours.

Harvest Demonstrations

So your hop cones are ready for harvest. Now what? Join Nebraska Extension for demonstrations of the Hopster 5P hops harvester in action.

Panhandle Research & Extension Center, Scottsbluff, NE lead by Stacy Adams and Gary Stone as part of the Season Extension Seminar for specialty crop growers.

The Nebraska Department of Agriculture (NDA) is a hosting Season Extension Seminar and hops production and harvesting demonstration Aug. 17 at the University of Nebraska Panhandle Research and Extension Center, 4502 Avenue I, in Scottsbluff.

The seminar, which will last from 9 a.m. until 5:30 p.m., is targeted to specialty crop growers, who will have the opportunity to connect with a retailers interested in sourcing local produce, learn about affordable financing options, and watch a cooking demonstration using locally grown produce.

There is no cost to attend, but individuals need to RSVP by Aug. 13 to casey.foster@nebraska.gov or 800-422-6692. A complimentary lunch will be provided.

The Season Extension Seminar (from 9 a.m. until 2 p.m.) will address the steps involved in implementing a variety of season extension methods, including crop selection, growing techniques, soil nutrition, disease and insect management practices, alternative hybrid varieties, reduced tillage strategies, intensive farming practices, season extension units (high tunnels), and market and selling strategies.

A university horticulturalist, extension educator, Farm Service Agency representative, local retailer, and NDA representative are scheduled to be the featured speakers. Attendees will receive an educational book related to specialty crop production.

The hops production and harvesting demonstration will begin at 2:30 p.m. It is intended for people who have an interest in hops, hobbyists, opportunists, or individuals exploring high-value specialty crops as a profit making venture.

Topics include: hops growth and development, trellising systems, plant production, an update on Nebraska hops cultivar evaluation research, harvesting and marketing. Participants will explore the hops research plot at the Panhandle Center and watch a hop cone harvest demonstration using the Hopster 5P cone stripping unit.

Friday, August 24, 2-4 PM, UNL East Campus Hop Yard

UNL East Campus, Lincoln, NE lead by Stacy Adams and Katie Kreuser. This informal event will demonstrate the use of the Hopster 5P, discussions on preparation & hop harvesting, and provide a tour of the UNL Agronomy & Horticulture’s quarter acre hop yard. RSVP to katie.kreuser@unl.edu.